creep fatigue test|accelerated creep damage : manufacturers The subsequent sections of this report examine, in detail, current design practice for basic creep- fatigue damage evaluation, creep-fatigue damage evaluation in the presence of detrimental . 4.1k 81% 13min - 1080p. Real Amateur Porn 1. Grasse vacche mulatte si scopano la fica chiusa e profonda. 931.5k 99% 33min - 720p. Real Amateur Porn 1. calde puttane .

{plog:ftitle_list}

web14 de nov. de 2017 · Subscribe: https://www.youtube.com/user/teamevga?sub_confirmation=1Sonic is fast, but so is the EVGA GeForce GTX 1080 Ti FTW3! Check out .

what is creep fatigue

The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) or creep-fatigue crack growth (CFCG) tests with .Creep-fatigue interaction behavior of ferritic steels and austenitic stainless-steels — covers properties, test methods and the latest models for applying the test data to components. 1.1 This test method covers the determination of creep-fatigue crack growth properties of nominally homogeneous materials by use of pre-cracked compact type, C(T), .

The subsequent sections of this report examine, in detail, current design practice for basic creep- fatigue damage evaluation, creep-fatigue damage evaluation in the presence of detrimental .

metal creep fatigue definition

metal creep failure

The results of laboratory specimen post-test examination are most effective for failure diagnosis when quantified, and the following sections review the way in which this can . We present detailed analyses of dwell characteristics of various waveforms of creep fatigue interaction tests performed on the nickel-based superalloy IN 718. We discuss the .The test programs for creep-fatigue test, such as creep crack growth (CCG), low-cycle fatigue (LCF), creep-fatigue (CF), fatigue crack growth rates (FCGR) and creep-fatigue crack growth (CFGR) are included in testXpert R. For .

Type 4 tests are generally known as thermo-mechanical fatigue tests. The strain-controlled fatigue test (type 1) is the most common one. Hold-Time Effects in Strain-Controlled Fatigue. The principal method of studying creep-fatigue interactions has been to conduct strain-controlled fatigue tests with variable frequencies with and without a .

The term ‘creep fatigue’ often appears when discussing fatigue or creep testing. Creep fatigue, which involves crack elongation over time, may occur when materials are subjected to stress and extreme temperatures. It is .Creep-fatigue interaction behavior of ferritic steels and austenitic stainless-steels — covers properties, test methods and the latest models for applying the test data to components. Creep-fatigue interactions in nickel-base superalloys being considered for use or already in use in advanced nuclear plants and in gas turbines — discusses .However, when creep-fatigue tests are carried out with a hold time at maximum tensile strain, there is a continuous decrease of number of cycles to fracture with the tensile hold time in vacuum as in air. In this alloy system creep-fatigue interactions are the dominating damage mechanism. While continuous fatigue gives rise to a transgranular .

We present detailed analyses of dwell characteristics of various waveforms of creep fatigue interaction tests performed on the nickel-based superalloy IN 718. We discuss the effects of different dwell modes (strain, stress, and mixed) on creep fatigue properties. Strain dwell tests cause relaxation/accumulation of the mean stress, and stress . 2.1. Mechanism of Creep-Fatigue Cracking. The development of creep-fatigue damage in most power plant steels depends on temperature, strain range, strain rate, hold time, and the creep strength and ductility of the material [1,2,3,4].In the absence of a significant hold time (and/or at relatively high strain rates), crack initiation and growth is fatigue dominated, .

tear composition test

be good measures for the predictability of creep-fatigue models when creep dominates. The creep fatigue tests with the relatively short hold times in stress control do produce extensively larger creep strains than corresponding relaxation tests but .

Creep Test The creep test, also known as the stress relaxation test, is a destructive way of evaluating a material’s durability and thermal stability. A creep test is one in which the specimen is heated for an extended period and supplied with a constant tensile force or tensile stress. . The Standard Test Method for Creep and Fatigue, ASTM .Creep-fatigue is the initiation and subsequent growth of flaws under cyclic load interspersed with hold periods at constant, or slowly varying, load. . controlled fatigue test with holds will fail in fewer cycles than an equivalent pure fatigue test with the same strain range and at the same temperature but without any hold periods. Similarly . Data that may be determined from creep-fatigue tests performed under conditions in which creep-fatigue deformation and damage is generated simultaneously include (a) cyclic stress- strain deformation response (b) cyclic creep (or relaxation) deformation response (c) cyclic hardening, cyclic softening response (d) cycles to formation of a single .This ASTM E2760-19e1 test is intended as a guide for creep-fatigue testing performed on materials for research and development, mechanical design, process and quality control, product performance, and failure analysis. The fatigue crack will begin on the point of the notch and extend through the sample. The result from this test method can be .

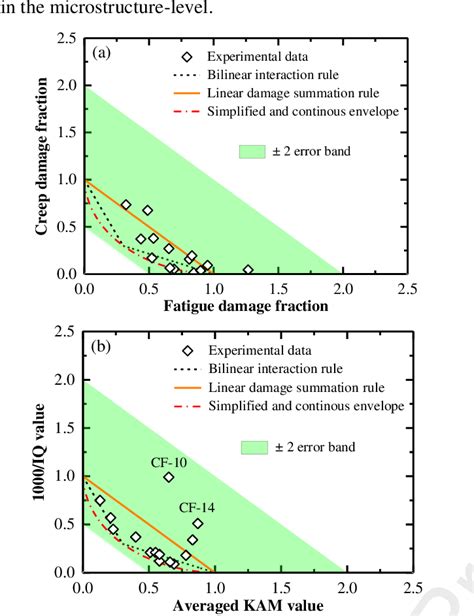

creep rate as a function of temperature and applied stress. The constant A, the exponent n, and the activation energy for creep Qc are material characteristics and can be determined from a series of creep tests. Several tests have to be carried out . Another observation from creep-fatigue interaction test results in Fig. 16 is that linear damage rule is conservative for all conditions, except for the loading block with R = 0.1 at 23 °C. The reason for longer lives in the presense of creep may be explained by crack formation and crack tip morphology in polyethylene .

Preliminary creep-fatigue test matrix for Alloy 709. ... 18. iv ABBREVIATIONS, ACRONYMS, AND INITIALISMS ANL Argonne National Laboratory AOD argon-oxygen-decarburization ART Advanced Reactor Technologies ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials . Complex service-like relaxation- and creep-fatigue tests with strain- and stress-controlled dwells and fatigue cycle durations of approx. 2200 s were performed exemplarily on a grade P92 steel at 620 °C in this study. The results indicate deviations in the prevailing creep mechanisms of long-term relaxation and creep dwells, affecting . For creep-fatigue test with an asymmetric trapezoidal wave, the average stress value of peak and valley shown in Fig. 7 (b) is often used to analyze the mechanical behavior [33]. It can be seen that the mean stress of this joint is negative (compressive) in the very beginning and becomes more negative with cycles. During the tensile holding .

The present work takes a new look at the high temperature strength of single crystal (SX) Ni-base superalloys. It compares high temperature constant strain rate (CSR) testing, creep testing, and out-of-phase thermomechanical fatigue (OP TMF) testing, which represent key characterization methods supporting alloy development and component design in SX material science and .

Creep.fatigue test cycles. ators. The cycles are simplifications of actual complex service cycles. Experimental replication of service histories would require complex programming achiev-able through a computer-controlled servo system. Usually, life prediction models are relied upon to link

Predicting creep-fatigue life from creep pro Creep-fatigue tests were conducted on 31 correspond well with the results of [5] as show fatigue test is shown in Fig.3. The relaxation rati e assessed according to ECCC recommendations for sub els by utilizing the logistic creep strain prediction method ssment are given in Table 1. The simultaneous appearance of creep voids and fatigue striations indicates a strong interaction between fatigue and creep, resulting in creep damage that reduces the fatigue life of CFI tests. Among the different hold directions, the combination of tensile and compressive hold ( Fig. 13 (e)) exhibits the highest number of creep voids, thus .

Failure diagnosis invariably involves consideration of both associated material condition and the results of a mechanical analysis of prior operating history. This Review focuses on these aspects with particular reference to creep-fatigue failure diagnosis. Creep-fatigue cracking can be due to a spectrum of loading conditions ranging from pure cyclic to mainly .E2714 Test Method for Creep-Fatigue Testing 3. Terminology 3.1 Terminology related to fatigue and fracture testing contained in Terminology E1823 is applicable to this test method. Additional terminology specific to this standard is detailed in section 3.3. For clarity and easier access within this document some In addition, several LCF tests were performed for a low strain rate of 1 × 1 0 − 4 /s and as fatigue–creep tests with a tensile strain dwell. TMF tests were performed as out-of-phase and fully constrained between 100 °C and 650 °C. The investigation of the damage mechanisms revealed that the predominant failure mode is a combination of . The design against fatigue and creep failure is of necessity based on short-term laboratory tests where failure is accelerated by testing at stress or strain levels or at temperatures in excess of .

In order to prevent the creep-fatigue failures, the following types of laboratory tests are often performed under strain cycling illustrated in Fig. 2. Those are carried out under isothermal condition under creep regime.creep tests are to interpreted. Figure 8.2 shows a typical creep testing setup. The basic results of a creep test are the strain versus time curve shown schematically in Fig. 8.3. The initial strain, εi = σi E, is simply the elastic response to the applied load (stress). The strain itself is usually calculated as the engineering strain, ε .

creeping fatigue definition

Handebol. 1. Quadra. 1.1. A quadra de handebol possui 40 por 20 metros. De cada lado, estão os respectivos gols que medem 2 por 3 metros. O piso é geralmente de madeira envernizada, ou ainda, emborrachado. 2. Origem.

creep fatigue test|accelerated creep damage